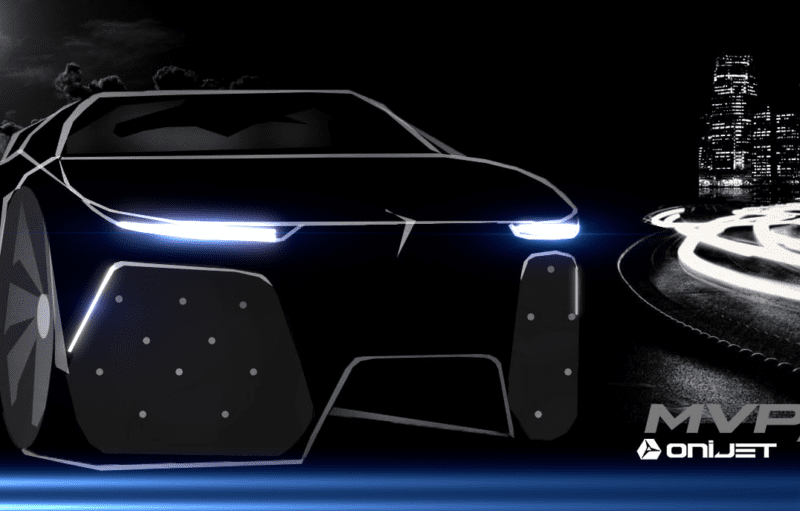

Introduction: In the realm of automotive brilliance, MVP1 emerges as a supercar that not only captivates with its speed and design but stands as a testament to the meticulous processes that ensure both precision and safety. Join us as we delve into the extraordinary journey of crafting MVP1—a masterpiece born from wind tunnel testing, crash testing, safety features, and a flawless supercar manufacturing process on an advanced assembly line.

Wind Tunnel Testing: Harnessing the Power of Aerodynamics MVP1’s journey begins with wind tunnel testing—an integral phase that fine-tunes the supercar’s aerodynamics for optimal performance. Every curve, contour, and surface is meticulously analyzed to reduce drag, enhance downforce, and ensure stability at high speeds. The wind tunnel testing phase isn’t just about speed; it’s about harnessing the power of aerodynamics to create a supercar that slices through the air with unparalleled precision.

Supercar Crash Testing: Ensuring Unrivaled Safety Safety is paramount in the design of MVP1, and crash testing plays a pivotal role in ensuring unparalleled safety features. MVP1 undergoes rigorous crash testing scenarios to simulate real-world collisions, ensuring that the supercar not only meets but exceeds safety standards. From frontal impacts to side collisions, every aspect is scrutinized to safeguard the driver and passengers within the robust structure of MVP1.

Supercar Safety Features: Beyond Standard Protocols MVP1 is not just a high-performance supercar; it’s a sanctuary of safety. The integration of cutting-edge safety features ensures a secure driving experience. From advanced driver-assistance systems to strategically placed airbags, MVP1 is engineered with safety at its core. The supercar’s safety features go beyond standard protocols, providing a layer of protection that complements its high-performance capabilities.

Supercar Manufacturing Process: A Precision Ballet The manufacturing process of MVP1 is a precision ballet where every component is crafted with meticulous attention to detail. From the selection of lightweight materials to the precision of CNC machining and 3D printing, each step contributes to the creation of a supercar that exemplifies engineering excellence. The manufacturing process of MVP1 is not just about building a car; it’s about sculpting an automotive masterpiece.

Assembly Line Excellence: Where Precision Meets Efficiency MVP1’s journey through the assembly line is a seamless dance of precision and efficiency. Each component, crafted to perfection, comes together to form the final masterpiece. The assembly line is a testament to the commitment to quality control and manufacturing tolerances, ensuring that every MVP1 that rolls off the line meets the exacting standards set for this elite supercar.

Conclusion: MVP1 is more than just a supercar; it’s a symphony of precision and safety. From the wind tunnel testing that refines its aerodynamics to the crash testing that ensures unmatched safety features, MVP1 is a marvel of engineering. The supercar’s manufacturing process and assembly line excellence complete the narrative, showcasing a commitment to crafting a vehicle that not only excites on the road but also prioritizes the safety and well-being of those who experience its unparalleled performance.